United States: focus on the development of high-temperature structural ceramics. At present, it is in the stage of large-scale use in the fields of aerospace technology, aircraft, nuclear engineering, automobile, medical equipment and mechanical power. Since 2000, the American Advanced Ceramics Association and the national Department of energy have jointly funded and implemented the 20-year American advanced ceramics development plan. The expected goal is that by 2020, advanced ceramics will become an economical and applicable preferred material with its superior high-temperature performance, reliability and other unique properties, and will be widely used in energy conservation and environmental protection, new generation information technology, biomedicine, high-end equipment manufacturing In strategic emerging industries such as new energy and new energy vehicles, demanders can choose to use advanced ceramic products with superior cost performance according to application requirements. The National Aeronautics and Space Administration (NASA) has implemented a large-scale research and development plan in the development and processing technology of structural ceramics, focusing on the replacement of ceramics in the key closed-loop of aeroengines and civil heat engines, and funding the research and industrialization of nano ceramic coatings, biomedical ceramics and photoelectric ceramics.

Japan: in recent years, Japan has taken advanced ceramics as a strategic industry, regarded it as a high-tech industry that determines its future international competitiveness, and continuously increased investment. Japan is in a leading position in advanced ceramic materials such as electronic ceramics, optical fiber and high toughness ceramics. The advanced ceramic sensitive elements produced in Japan have occupied the main share of the international market, and various advanced ceramic products, including thermal, pressure sensitive, magnetic, gas sensitive and photosensitive, monopolize most of the market; In the research and development of foam ceramics, superplastic ceramics, plastic composite ceramics, advanced ceramic materials and ceramic components, high-performance ceramic batteries, ceramic engines and other research and development, they are in the leading position.

EU: EU countries take functional ceramics and high-temperature structural ceramics as the main research objects. At present, the focus of research is the new material technology applied in power generation equipment, such as ceramic piston cover, exhaust pipe lining, turbocharged rotor and gas turbine rotor. In addition, some EU countries have obvious advantages in advanced ceramic machinery and equipment.

3

Electronic ceramics

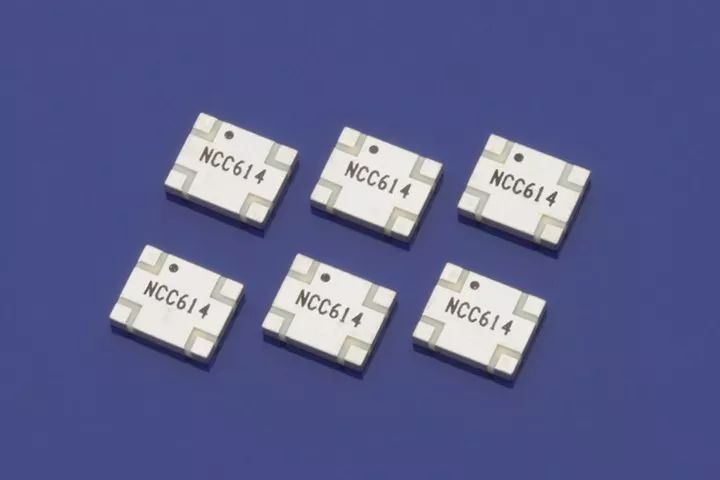

Electronic ceramics are relatively mature technical products among advanced ceramics, accounting for about 65% of the market share of advanced ceramics. It is mainly used for chip, capacitor, integrated circuit packaging, sensor, insulator, ferromagnet, piezoelectric ceramics, semiconductor, superconductor, etc. The main materials are barium titanate, zinc oxide, lead titanate zirconate, lithium niobate, aluminum nitride, zirconia and alumina. With the rapid development of information industry and electronic consumer industry, industrial electronic products and consumer electronic products will maintain a rapid development trend, and there is a huge demand for electronic ceramics. It is expected that the global demand for electronic ceramics will exceed 40 billion US dollars by 2020.

4

In addition to being used for measurement, diagnosis and treatment, bioceramics are mainly used as substitute materials for biological hard tissues. They can be used in orthopedics, plastic surgery, oral surgery, cardiovascular surgery, ophthalmology, otolaryngology and general surgery. At present, biomedical materials have become the focus of research and development by scientists all over the world. 70 ~ 80% of domestic biomedical materials and products depend on import and basically belong to imitation. China’s biomedical materials account for only 2% of the global market share, and most of the product technology level is in the primary stage. With the aging of social population, by 2020, China will need about 800000 sets of artificial joints / year, 1.6 million vascular stents / year and 1.4 million intraocular lenses / year, and the demand for bioceramic materials will increase significantly.

5

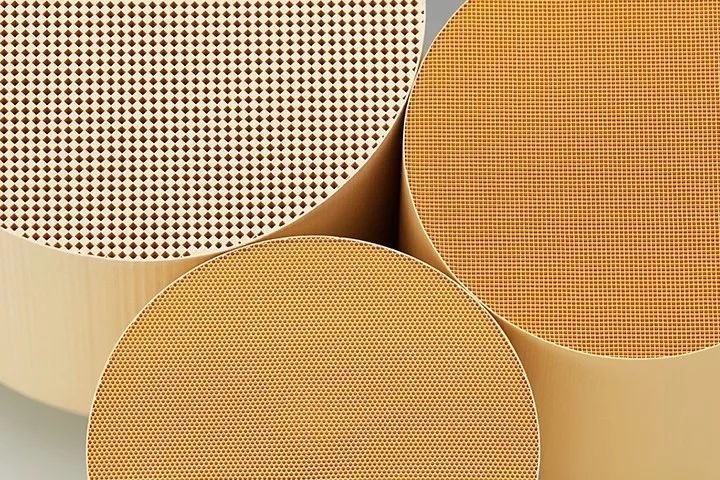

With the rapid development of economy, the rapid increase of energy demand and the huge amount of industrial and domestic waste, energy conservation and environmental protection have become a major issue of increasing concern to the international community. Under the circumstances of energy shortage and increasingly serious environmental deterioration, advanced, efficient, energy-saving and environmental protection technologies can realize energy-saving regenerative thermal waste incinerators and honeycomb ceramics for energy-saving regenerators in smelting industry, ceramic membranes and equipment for hot gas purification and water treatment, series of ultra / ultra-high voltage suspension porcelain insulators for UHV AC transmission technology and equipment, silicon carbide ceramic parts for heat storage and heat exchange A series of ceramic products for photovoltaic industry will get a rare development opportunity.

6

Aerospace ceramics

Aerospace ceramic applications mainly involve bulletproof armor ceramics for helicopters, aircraft brake disc materials, ceramic diaphragm materials for satellite batteries, infrared stealth / camouflage coatings, ceramic bearings, ceramic radome materials for missiles, etc. At present, the application research in aerospace mainly focuses on the heat-resistant materials of rocket nozzles, the thermal insulation tiles of spacecraft, composite engineering ceramic materials and the observation window coating of spacecraft, especially the research and development of ceramic fibers with light weight, heat resistance, ablation resistance, high melting point and high strength.

7

In recent years, nano ceramics have attracted much attention. The sudden change of ceramic materials and ceramic materials will lead to a wider range of scientific properties and ceramic materials. At present, the prepared nano ceramic powders include Al2O3, ZrO2, SiO2, si2n, SiC, BaTiO3, TiO2, etc. The development of nano ceramics has driven the development of some new rapid sintering equipment, such as vacuum sintering process, microwave sintering process and plasma sintering technology (SPS).

8

The absolute value of thermal expansion coefficient is less than 2 × Materials at 10-6 / ℃ are called low expansion materials, and materials with expansion coefficient close to zero are ultra-low expansion materials. Low expansion ceramics, especially zero expansion ceramics or negative expansion ceramics, can be used as high-tech materials such as engine main parts, aviation material blades, stove gasket, circuit substrate, astronomical mirror blank and radome, high-temperature observation window, precision measurement and other devices, carrier and filter, immobilization of nuclear waste, sealing materials and so on.

Summary

Advanced ceramics, as basic raw materials and core components, will usher in broad application and market prospects in the opportunity of vigorously developing strategic emerging industries.

reference material:

Zhang weiru et al Research status and development trend of advanced ceramic materials Sinoma high tech materials Co., Ltd

Song Tao et al Development status and trend of advanced ceramics at home and abroad Shandong industrial ceramics research and Design Institute Co., Ltd

Zhang Wenyu Research and application of advanced ceramic materials The 725 Research Institute of China Shipbuilding Industry Corporation