Bulletproof vests, also known as bullet proof vests, are used to protect the human body from bullet heads or shrapnel. The bulletproof jacket is mainly composed of a jacket and a bulletproof layer. The jacket is usually made of chemical fiber fabric, and the bulletproof layer is generally made of metal (special steel, aluminum alloy and titanium alloy), ceramic sheet (boron carbide, silicon carbide and alumina), FRP and ultra-high molecular polyethylene fiber. Among them, the bulletproof layer can absorb the kinetic energy of warhead or shrapnel, has obvious protective effect on low-speed warhead or shrapnel, and can reduce the damage to human chest and abdomen under the condition of controlling a certain depression.

According to the different degree of hardness and softness of the bulletproof layer, bulletproof clothing can be divided into three types: software, hardware and soft and hard complex. Soft bulletproof clothing absorbs impact energy with high-performance textile fiber, while hard bulletproof clothing is generally based on insert plate, which uses metal or ceramic insert plate to play a protective function. Composite bulletproof clothing is lined with soft materials and reinforced with hard materials.

The hardness of the composite shell made by goody2 company is relatively higher than that of the composite shell made by goody2 company, which can be traced back to 196 mm. The hardness of the composite shell made by goody2 company is the same as that of the composite shell made by goody2 company, which can be used to simulate the high-speed shooting of the target, The ceramic composite armor is deeply studied. In 1965, Goodyear launched boron carbide bulletproof armor suitable for military aircraft equipment. Since then, as a new type of bulletproof armor, ceramic materials have been gradually applied to military aircraft, tanks, ships and individual bulletproof vests.

The biggest difference between ceramic materials and traditional metal materials in bulletproof principle is that metal materials can absorb the energy of warhead through plastic deformation, while ceramic, as a brittle material, its plastic deformation is almost 0. Therefore, under the action of large impact force of warhead, ceramic materials mainly absorb energy through micro crushing process, which can be roughly divided into initial impact stage, erosion stage and deformation and fracture stage. The surface layer of bulletproof ceramic can passivate the warhead and crush the surface into fine and hard particles. When the blunt projectile continues to go deep, the bulletproof ceramic forms a fragment layer, the tensile stress inside the material breaks the ceramic, and the remaining energy is absorbed by the back plate. Therefore, the greater the elastic modulus and hardness of ceramics, the smaller the density, and the stronger the kinetic energy absorption capacity of ceramics, that is, the better the bulletproof performance.

The most successful application of ceramic materials in bulletproof clothing is the “interceptor” bulletproof clothing in active service of the US Army. The “interceptor” bulletproof clothing is composed of a detachable and washable tactical vest type jacket, a Kevlar soft bulletproof inner layer and two boron carbide bulletproof plates at the front and rear. It was equipped with the U.S. military in January 2001. The “interceptor” without protective plates weighs about 3.81 kg, while the full set of “interceptor” bulletproof clothing weighs only 7.44 kg, which is 4.08 kg lighter than the combination of old-fashioned bulletproof clothing pasgt / SAPO.

In addition to being portable, bulletproof ceramics are also characterized by strong protection ability, which stems from the high specific strength, large elastic modulus and high hardness of the ceramics themselves. In August 2005, a video of snipers attacking US troops in Iraq shot by Iraqi anti US forces circulated on the Internet. However, its content is more like an advertisement for the “interceptor” bulletproof vest of the U.S. military: the attacked U.S. medical soldiers stood leisurely by the road. After a “bang” shot, the bullet from the SVD sniper rifle instantly hit the chest of the traditional Chinese medicine guard. The strong impact made the latter soar and fall to the ground. But in a twinkling of an eye, the medical guard stood up again, looked in the direction of the attack with a gun, and then ran to the back of the Hummer to look for cover… However, the medical guard was not intact. The strong impact of the SVD warhead caused red bruises on his chest. According to the U.S. military’s evaluation of the “interceptor” bulletproof vest, the bulletproof grade of the vest itself reaches grade I and can resist 9mm pistol bullets. After inserting a 1.81kg boron carbide light weapon protection insert plate in the front and back, the defense grade can be increased to grade IIA to resist the 7.62mm gun shells launched by AK47. However, the price of this plug-in board is quite expensive. The total price of the fully equipped “interceptor” bulletproof vest is as high as $1600.

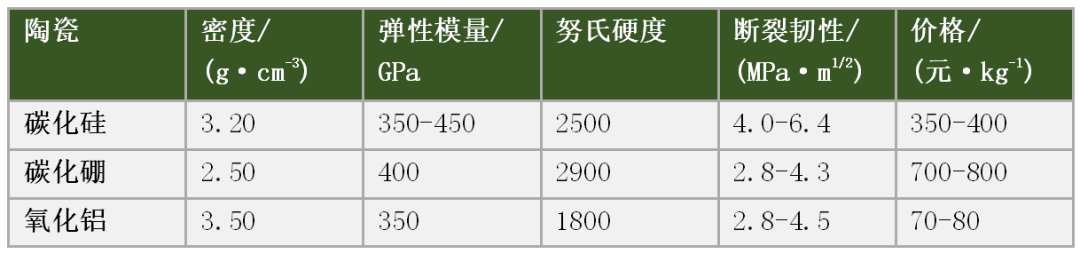

At present, the ceramic materials that have been applied to bulletproof clothing are mainly alumina, silicon carbide and boron carbide. The main performance indexes of these three bulletproof ceramics are shown in Table 1.

Table 1 three commonly used bulletproof ceramic materials

Ceramic materials used in bulletproof clothing can have both protective ability and portability pursued by individual soldiers. At present, among the common bulletproof ceramics, alumina is relatively cheap compared with the other two, which can meet the general bulletproof requirements. However, silicon carbide and boron carbide are expensive, and the application prospect of boron carbide is more clear. However, due to the high price, it is generally applied to the parts with the highest bulletproof requirements. For example, on the Changhe wuzhi-10 fully equipped by the people’s Liberation Army in 2016, boron carbide ceramic armor plates capable of resisting 12.7mm large caliber machine gun bullets were installed on both sides of the particularly fragile cockpit shoulder of the helicopter; The ammunition compartment under the crew compartment of the Apache helicopter known as the “flying tank” of the U.S. military is directly related to the safety of people and aircraft. Therefore, it is equipped with armor composed of boron carbide ceramics and Kevlar fiber, which can directly resist the attack of 23mm shells, while other relatively unimportant parts only use bulletproof glass.