According to the classification of ceramic membrane structure and production process characteristics, ceramic membrane can be divided into tubular ceramic membrane and flat ceramic membrane. The wall of tubular ceramic membrane is densely covered with micropores. Under the action of pressure, the raw material liquid flows in or outside the membrane, and small molecular substances pass through the membrane and macromolecular substances are intercepted by the membrane, so as to achieve the purposes of separation, concentration and purification. The surface of the flat ceramic membrane is densely covered with micropores. Within a certain range of membrane pore size, the permeability varies with the molecular diameter of the permeated substances. With the pressure difference on both sides of the membrane as the driving force and the membrane as the filter medium, when the feed liquid flows through the membrane surface, only water, inorganic salts and small molecular substances are allowed to pass through the membrane, while macromolecular substances such as suspended solids, glue and microorganisms in the water are prevented from passing through, so as to achieve the purpose of separation.

(source: Dai Jinguo et al. Application of flat ceramic membrane in sewage treatment)

Application advantages of ceramic flat membrane materials

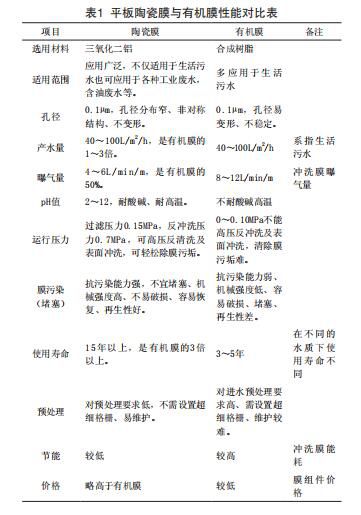

As a new membrane separation material for water treatment developed internationally in recent 10 years, ceramic flat membrane material has the advantages of high mechanical strength, good chemical stability, high water permeability, oxidation resistance and easy cleaning and regeneration compared with the existing organic membrane materials. It can effectively solve the technical problems existing in the engineering application of other membrane materials, such as short service life, easy to be corroded by acid and alkali, and is especially suitable for special media Treatment of high concentration organic wastewater and refractory sewage. At the same time, compared with traditional tubular ceramic membrane materials, ceramic flat membrane materials have the advantages of low manufacturing cost of membrane materials and low investment and operation cost of membrane equipment. It is a new inorganic membrane separation material with great development potential being developed in the world. Ceramic flat membrane is used for membrane water treatment, which can realize the advanced treatment of industrial wastewater from printing and dyeing, petrochemical and pharmaceutical industries, reduce pollutant discharge, and then realize the resource reuse of industrial wastewater.

Ceramic flat membrane is mainly composed of membrane support and membrane separation layer. According to the shape and performance requirements of membrane materials, the preparation technology of ceramic flat membrane support is mainly extrusion and compression molding at present. The preparation technology of sol gel technology and solid particle sintering technology are mainly used. The developed ceramic flat membrane materials mainly include silicon carbide, titanium dioxide, alumina and so on. Among them, aluminum oxide ceramic flat film has the advantages of wide source of raw materials, excellent comprehensive properties, easy low-temperature sintering and low manufacturing cost.

Development status of ceramic flat membrane materials

The development of ceramic flat membrane materials began at the beginning of this century. The world’s first ceramic flat film was completed by German ITN company in 2006. Subsequently, sje rhombus company in the United States, mingdianshe company in Japan, ceraflo company in Singapore and Shandong industrial ceramics research and Design Institute Co., Ltd. in China also carried out corresponding research work.

With the encouragement of relevant national policies, the investment of film making enterprises in R & D is increasing, the technical bottleneck is breaking through, and the industrialization process is accelerating. The membrane industry has formed a relatively complete industrial chain, including the R & D and sales of upstream membrane materials, the production and sales of midstream membrane components and the application of downstream membrane engineering. Water treatment is an important downstream application field of membrane industry. At present, domestic microfiltration / ultrafiltration technology is relatively mature and accounts for a relatively low proportion, and its share in the water treatment market is expected to increase in the future.

China’s ceramic ultrafiltration membrane and microfiltration membrane have reached the international advanced level, and the production scale is in the forefront of the world. However, there are few products competing with foreign leading products on ceramic nanofiltration membrane. The next step in the development of flat ceramic membrane in China is to develop nanofiltration level flat ceramic membrane. At present, foreign companies represented by Germany ITN and Japan mingdianshe have realized the commercial application of inorganic flat membrane MBR, of which Japan mingdianshe has entered the Chinese market. Ba’an water has acquired 67.65% of the equity of German ITN company, and the flat ceramic membrane technology in China has been applied to the field of seawater desalination.

Relying on its own research advantages and rich technical accumulation in the field of porous ceramic materials, Shandong industrial ceramics research and Design Institute has completed the research, development and marketization of a series of large-size ceramic membrane materials and components for water treatment through continuous and high-intensity R & D investment, which has greatly reduced the manufacturing cost of membrane materials, and the development and application of products have been widely praised by users. Shandong industrial ceramics research and Design Institute has played a leading role in the research and development, standardization and automatic production of nano ceramic flat membrane. Other companies such as Jiangsu JiuWu High Tech Co., Ltd., Hefei Shijie membrane Engineering Co., Ltd., Xiamen Sanda Membrane Technology Co., Ltd. and Jiangsu Xinshi high temperature materials Co., Ltd. have also actively carried out the manufacturing and R & D of domestic flat ceramic membrane.

(source: Shandong industrial ceramics research and Design Institute)

Recently, China’s covid-19 editor from Shandong industrial ceramics research and Design Institute was informed that it received a letter from a department on building a new crown pneumonia emergency ward in a city, and urgently needed ceramic flat membrane sewage treatment equipment for COVID-19 isolation ward medical waste water treatment. After three days of intensive production day and night, Shandong Institute of technology and ceramics successfully completed the production and assembly of ceramic flat membrane modules and delivered them on time.

Reference source:

Tang Yudong, Xue Youxiang, Zhao Shikai, etc Preparation of ceramic flat membrane for water treatment Shandong industrial ceramics research and Design Institute Co., Ltd

Dai Jin, Qin Yulan, Gao Minghe, etc Application of flat ceramic membrane in sewage treatment Guangxi biqingyuan Environmental Protection Investment Co., Ltd

Shandong industrial ceramics research and Design Institute